15 January to 15 March 1944

During this two month period the company has continued to operate on the basis of four main sections: Ammunition, Armament, Automotive and Supply. The increased number of bombing missions has caused a corresponding increase particularly in the activities of the Ammunition Section, which is charged with the maintenance of the Bomb Dump. On several occasions the whole company has participated in unloading and stacking bombs. In cooperation with the Engineers this unit completed the construction of a third echelon repair garage. Prior to this time automotive repair work was performed out-of-doors under most adverse conditions. Recognizing the importance of the bicycle as a means of conveyance on the station, the bicycle repair shop has been further developed.

On 25 January, Capt Curt A. Remfrey, Commanding Officer, was transferred to the Ninth Air Force. 1st Lt Jack A. Teufel assumed command on this date and was appointed Wendling Station Ordnance Officer. As a result of this shift, 1st Lt Arthur H. Hand was appointed Supply and Armament Officer. On 1 March, 2nd Lt Charles E. Dye, Ammunition Officer, was promoted to the rank of 1st Lt. The vacancy existing in the Officer T/O was filled with the assignment on 10 March of 1st Lt Walter P. Haar as Automotive Officer.

Under the supervision and control of the Station Ordnance Officer, a program and training schedule for Bomb Reconnaissance was developed. All personnel of this unit have been assigned to squads and lectures and practice alerts were held. To prepare the unit further for this most important activity, five non-commissioned officers and one officer have attended Bomb Reconnaissance School for a course of one week's duration. It is significant to note that during the past month squads have made a reconnaissance on four occasions, three as a result of bombs being jettisoned by our own aircraft and one as a result of enemy action.

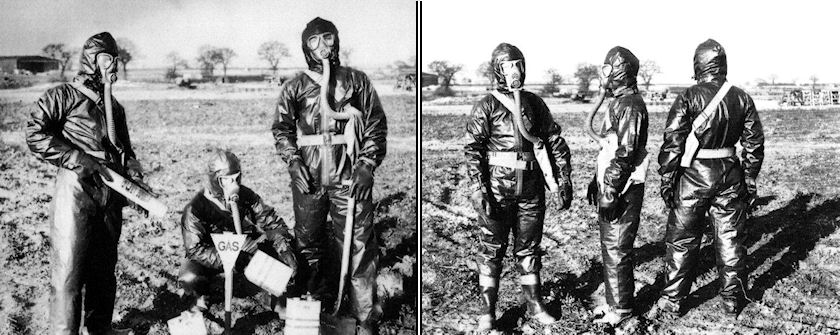

In a series of lectures given by Gas Non-Coms, defense against chemical warfare has been stressed. This program extended over a period of six weeks, a separate subject being discussed each week. Two enlisted men have acquired special training at school in the waterproofing of vehicles and the operation and maintenance of Diesel engines. Under the supervision of the Commanding Officer, several enlisted men of this unit have enrolled in Army Forces Institute Correspondence courses. The men are thus using their spare time most profitably in preparing themselves for future civilian jobs.

An event of special significance and one in which this company takes justifiable pride occurred on 20 January. On this date two enlisted men, F/Sgt Vernon L. Olson, 20846563, and Tec 5 Finney D. Voelkel, 33417238, were awarded the Soldier's Medal for heroism displayed at this station 5 December 1943 (GO #17, HQ 8AF, 20 January 1944). During the bomb loading period of a B-24 aircraft, the ship caught fire, exploded, and was eventually completely consumed in the fire. Due to the intense heat, 500 # demolition bombs and machine gun ammunition exploded at various intervals. In the face of great danger and at the risk of their lives, F/Sgt Olson and Tec 5 Voelkel chose to drive to safety an oil truck and a cletrac which were parked about 20 beside a flaming gasoline trailer. [Note: This incident occurred during the early morning of 5 Dec 1943; the plane was #42-7556, Exterminator II.]

This unit has held one company dance at the Enlisted Men's Club on this station. This affair was an outstanding success. Plans are now being made for a second dance to be held on March 25th. A company basketball team was entered in the station league and to date has played and won two games. A softball team has been organized and will be entered in the station league.

1 March to 1 May 1944

The activities of the unit during this period have kept pace with the ever-increasing number of bombing missions performed by the Group. Personnel of the Ammunition Section have been engaged in round-the-clock work in unloading convoys, stacking bombs, preparing the squadrons for bomb-loading operations, and in the many other jobs incident to the successful maintenance of a Bomb Dump. The Automotive Section has added a spare parts section and an office to the third echelon repair garage. In cooperation with the Engineers the cement apron surrounding the garage has been extended and a direct road from the Motor Pool has been constructed. The completion of the Automotive Shop has contributed materially to the reduction of dead-lined vehicles as is evident from the comparison of records of the last six months. The Armament Section, in addition to their regular duties of third echelon maintenance of machine guns and individual weapons, have initiated a procedure for periodic inspection of all hand and shoulder weapons on the station. One inspection has been completed during this period.

The practice of sending personnel to school to acquire specialized knowledge has been continued. To implement further the program and training schedule for Bomb Reconnaissance, 1st Lt Jack A. Teufel and two non-commissioned officers, M/Sgt Howard F. Sinzinger and T/Sgt Joseph H. Dreher, have attended Bomb Reconnaissance School for a course of one week's duration. 1st Lt Arthur H. Hand attended a five-day course on Radio Suppression and Banding, with particular reference to motor vehicles.

Personnel of the Automotive Section have experimented with a modification of the Holland Hoist on bomb service trucks. This modification, which facilitates the operation of the hoist, has been approved by 2nd Bomb Division. Plans and drawings have been forwarded to Eighth Air Force for final approval and acceptance.

On the night of 25 March a company dance was held at the Enlisted Men's Club on this station. This was the second affair to be held in the ETO and proved to be an outstanding success. Plans are now being formulated for a third dance.

The company basketball team played several times a week, and all games were well attended by the men. In the station elimination tournament, the team reached the quarter finals.

With the advent of warm weather and long days, softball has become the leading recreational activity. A field adjacent to the company site has been converted into a softball diamond by the men of this unit. The infield has been leveled off, a backstop erected, and foul lines marked off. Several intra-company games have been played for the purpose of selecting a team to represent the unit in the station league. To date, the team has played and won one practice game.

1 May to 1 June 1944

The ever mounting tempo of bombing missions on the part of the Group has manifested itself primarily in Bomb Dump operations. In addition to three Ammunition Section Crews working on a twenty-four hour schedule, daily details from the other sections of the company have participated in unloading convoys, inspecting fuses, uncrating bombs, and processing .50 caliber ammunition.

The Armament Section has completed a second inspection of all hand and shoulder weapons on the Station. In the interests of Station Defense, personnel of this section have designed and constructed gun mounts for .50 caliber ground guns.

The Automotive Section has collaborated in the welding of these mounts and in addition has supervised the mounting of guns on trucks in the Motor Pool. During this period, the Automotive Officer, Lt. Haar, and Tec 5 Palmer and Tec 5 Kozakiewicz have attended a three day course in Electrical Bonding of Vehicles. Two EM, Tec 4 Merritt and Tec 5 LaTour have completed a one week's course at Bomb Reconnaissance School.

On the night of 27 May, this unit held its third dance in the ETO at the Enlisted Men's Club on this Station. This party was held in cooperation with Headquarters Squadron and the Quartermaster Company and proved to be very successful. Alerts and the arrival of convoys have made it quite difficult to keep the company soft ball team intact. However, in spite of these difficulties the team has been entered in the Station League and to date has played three games.

1 June to 1 July 1944

With bombing missions on the part of the Group reaching their highest level in support of the Invasion, operations of the unit during this period centered about the Bomb Dump. The following excerpt from the Daily Activity Report of the Ammunition Section describes in some detail this rather hectic period. " 'D' Day opened with a bang at the Bomb Dump as well as on the beaches of Normandy. On the evening of 5 June, 'D' Day minus one, the Bomb Dump was filled with trucks. Everyone was aware of the tension in the air and there were many speculations about 'D' Day, but no one realized that this was 'it'.

At 1600 hours a convoy of 250# bombs rolled into the dump. This was quickly followed by a convoy of trucks from AAF Station 143 who were to "borrow" 780 fragmentation bombs. This convoy arrived without sufficient men to accomplish the loading. With two convoys already in the dump, one thought the maximum of confusion had been reached, but the final blow fell when the Squadrons streamed into the area, preceded by a telephone call from Station Ordnance that two missions would be made on the following day.

For the next twenty days and nights life was just a continued task of unloading and loading trucks and putting out one or two missions a day. The biggest day of the month occurred, of all days, the day of the Station 100th Mission party. On this day, we received 1400 fragmentation bomb clusters and 1614 250# bombs and put out a '100# mission'.

During the last week of the month both convoys and missions slacked off, but not a day too soon, for all the men in the Ammunition Section were, to use a favorite Bomb Dump expression, 'ready for the rack' "- - - - By the end of the month the salvage problem was well under control, 100 truckloads having been hauled to the salvage depots.

In spite of the fact that the automotive and armament sections maintained skeleton crews at their respective shops in order to provide as many men as possible for the Ammunition Section, their operations continued at normal levels. The monthly inventory of Job Orders shows the following work done by the Automotive Section: (1) 103 repair jobs on vehicles from this station. (2) 5 repair jobs on vehicles from other Stations. (3) 10 Station ambulances repainted in accordance with new regulations. (4) 12 field range units reconditioned for the mess halls.

During this period there was a shortage of supply on some items for caliber .50 Aircraft Machine Guns. To ease this shortage and thus avoid bottlenecks in maintenance, the Automotive Machine Shop modified several hundred over-sized firing pins and turned out a quantity of bolt studs. In addition, the machinists made several gears for power take off units on oil service trucks. The Welding Shop welded eight ground machine gun mounts and worked on twenty airplane engine mounts.

On 24 June, 1st Lt Arthur H. Hand, Supply and Armament Officer was transferred to the 445th Bombardment Group (H). Lt Hand had been assigned to this unit since its activation. To date this vacancy in the Officer T/O created by this transfer has not been filled.

The altered schedule of operations made it impossible for the Company Softball team to play any games in the Station League, nor for the unit to participate in any planned recreational activities. Several members of the company, however, continued to play for the Station Baseball and Softball Teams.

It is interesting to note that this unit arrived on the Station the very day the Group was completing its first mission. Therefore, in connection with the Group celebration of its 100th Mission, the company takes justifiable pride in having been an integral part of this achievement.

1 July to 1 August 1944

The sharp decrease in the number of bombing missions during the first week of July, gave the Ammunition Section an opportunity to direct its efforts to cleaning up the salvage which had accumulated since D-Day. In all, a total of 135 truck-loads of salvage were sent out in the first seven days of July.

However, during the ensuing weeks convoys rolled in continually, and revetments once more were filled with rows of stacked bombs. The eighteen convoys unloaded during the seven day period from 7 July to 15 July contained 190 1000# bombs, 1011 500# bombs, and 1938 100# bombs. Seventeen additional convoys rounded out July's activities which increased in tempo as the month progressed.

Inasmuch as Ordnance activities are usually relegated to the background and are taken for granted, it might be interesting to note a few figures which will serve as an index of the work done at the Bomb Dump. During this period 1367 tons of bombs were unloaded from convoys. During the same period 840 tons were 'put out' for bombing missions. The unloading process involves uncrating, knocking off bands, and stacking; 'putting out' a mission involves assisting the squadrons in loading their trailers and very often re-stacking the bombs when a mission is scrubbed. Add to this inspection of fuses, linking and inspection of .50 caliber ammunition, storage and issue of pyrotechnics, maintaining a stock of practice bombs, and it is evident that the 19 men who comprise the Ammunition Section are doing a big job.

As a result of the Bomb Dump explosion at Metfield, the Ammunition Section realized that 'it can happen here', particularly with the introduction of new and more sensitive explosives. Consequently, all safety regulations and precautions were thoroughly checked and tightened up. All of the men in the section and most of the men in the Company were given an opportunity to visit the scene of the explosion at Metfield. This was done to impress clearly and vividly on the minds of the men, just what results when even the slightest safety measures are discarded.

The 3rd Echelon Garage completed 112 jobs in spite of a rather tight situation in the supply of spare parts. As an example, exhaust pipes on ½ ton vehicles were repaired with flexible steel tubing. Modifications of this kind have been made several times in order to get vehicles off the 'deal-line' when parts were unavailable.

The machine shop assisted the 844th Engineers working on this Station by making two valves for a water pump engine. These valves were turned from salvaged Ford valves. In addition, GMC brake drums have been replaced for Shipdham.

The Armament Section devoted this period to the modification of carbines on the Station plus a small amount of 3rd Echelon maintenance required to keep all aircraft weapons in suitable working condition. Special tools are required in the thorough inspection of aircraft weapons, and also to facilitate and to remove any possibility of error in their assembly. These requirements were met by the construction in the Armament Shop of firing-pin gauges, oil buffer tubes, back plate buffer discs, piston-rod heads, and valve gauges for oil buffer tubes. These tools have proven of inestimable value inasmuch as considerable time is saved and all chances of error have been eliminated.

The Armament Section has also made plans whereby the mobile shop truck can be reconverted within a few hours should it become necessary to operate under field conditions.

On 15 July 1944, Lt. Jack A. Teufel, Commanding Officer of this unit and Station Ordnance Officer, was promoted to the rank of Captain. Captain Teufel has been assigned to this unit since its redesignation in May 1943.

During the last few days of the month plans were drawn up for the part this unit was to play in the 8th Air Force War Bond Drive. Arrangements were also made for the Company Dance to be held at the Enlisted Men's Club, this Station, on 12 August in conjunction with Headquarters Squadron and 1217th Quartermaster Company.

1 August to 1 September 1944

The report of the Ammunition Section, recording the daily activities at the Bomb Dump, reveals the unspectacular but important work that Ordnance is performing in the aerial offensive against Europe. It might prove interesting to quote at random from this Report for the month of August.

Sat. Aug 12: All ammunition men were uncrating 100# bombs. About 1000 bombs were uncrated. At midnight, a convoy of Frags (fragmentation bombs) came in. Ten ammo men started unloading when a mission of 100# bombs was called at about 0130 hours. Three men put out the mission which consisted of issuing wires, clusters, and fuzes. All were issued by 0500. The Frag convoy was unloaded by 0545.">

"Tues. Aug 15: A convoy of 1800 100# bombs was unloaded with the aid of 4 chemical men. That evening 26 truck-loads of salvage were loaded with the aid of 20 men from the other sections of the company. That night a 500# bomb mission was pulled at 2300 hours. During the above happenings 3 men were injured. One dropped a bomb on his foot; another received a bad cut on knee cap, while the other cut his finger unloading 100 # bombs, nearly severing it."

"Thurs. Aug 10: Ten trucks loaded with salvage. Six men linking ammo. Three men in fuze shack. Four men inspecting Frags. Convoy of 500# bombs unloaded in afternoon. Mission of M57 250# bombs called-39 planes."

It is quite evident from these excerpts that round-the-clock activity is the rule rather than the exception at the Bomb Dump. In spite of the fact that the operation of the Group during August dropped off somewhat in comparison with those of July, the number of convoys unloaded at the Dump showed an increase. This was due to the fact that huge inventories of bombs were accumulating at railheads. It was necessary, therefore, to distribute stocks in excess of maximum levels to the various AAF Stations and thus relieve the choked transport system.

A most important and interesting project was started at the 3rd Echelon Repair shop during this period. In the interest of economy of effort, a Bomb service truck was modified for the purpose of using the engine power to lift the bomb load. The parts required for this modification were as follows: power take-off from 1½ ton Chevrolet, winch from ½ or ¾ ton Dodge, a drive shaft to connect the two units, pulley wheel similar to the wheel on end of bomb service truck boom, and material to make gear-shift lever. The successful completion of this job points the way to similar modification of all bomb-service trucks on the Station.

It further illustrates how ingenious modifications by one branch of Ordnance facilitate the operations of another.

The Shop during this period completed 100 jobs of a varied nature. Two valve jobs performed for the 844th Engineers working on the Station were of particular interest because they involved the use of the shop trucks at the scene of engineer operations. Under field conditions, the activities of the Automotive Section would largely fall into this pattern.

On 12 August the Company held its fourth dance in the ETO. This affair was held in conjunction with Headquarters Squadron and the 1217th Quartermaster Company at the Enlisted Men's Club on this Station. This arrangement proved to be very successful on this occasion as it had in the past.

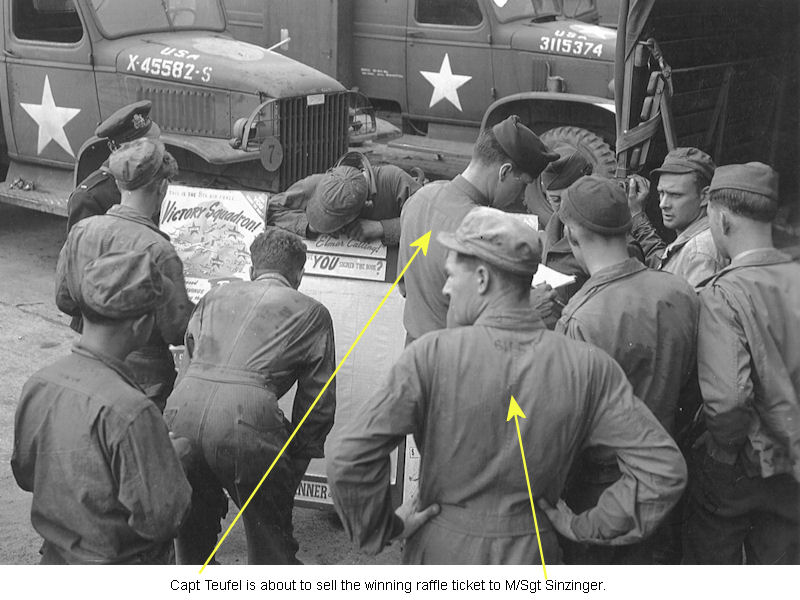

The response of the men in the company to the Eighth Air Force Victory Squadron War Bond Drive was most gratifying. A quota of $1,113.30 was set for this unit. On the second day of the drive this quota was reached and exceeded. At the end of the month the sales totaled $3,750.00, roughly 300% of the quota. The company takes pride in the fact that it had the second highest total sales of all the units on this Station.

A volley ball court was erected in the company area during the last period. Many of the men in the unit have taken advantage of this last recreational facility during the noon hour break and during the early hours of the evening.

1 September to 1 October 1944

The Ammunition Section during this period continued to play its important part in the operations of the Group. Quite naturally the tempo of activities rose and fell with the frequency of bombing missions and the number of aeroplanes participating in any single mission. However, it is axiomatic to say that the work at the Bomb Dump is never completed. Even a rapid perusal of the Daily Activity Report during this period reveals this fact. And further, it reveals that the work does not fall into any apparent pattern or routine. Men constantly switch from one job to another depending on their relative priority. One day a man is knocking bands off bombs, the next he is stacking, the third he is loading salvage, and the fourth uncrating bombs. Yet this all culminates in the performance of the all-important mission of the Ammunition Section: to have the bombs ready when they are needed for a mission.

A few excerpts from the Daily Activity Report of September illustrate these generalizations.

"Tuesday: Loaded 6½ trucks with salvage. Stacking 1000# bombs and knocking rings off 250# bombs. A convoy of M-57 came in about 1700 hours and was unloaded by 2130. Mission of M-57 called about 2130. 12 ships."

"Thursday: Five men moving nose fuzes from #9 shack to #12 shack. Loaded 6 trucks with salvage and AC trailer. Stacking 1000# bombs into revetments. Loaded 16 trucks with salvage. Mission of 1000# called at 2100. 39 ships. Finished 2330."

"Monday: Four men inspecting fuzes. Six men linking ammo. Two men filling practice bombs. Three men stacking 250# bombs into revetments. Mission of M-64 pulled 0130. 25 ships."

"Tuesday: Two men in fuze shack. One man modifying parachute flares. Four men knocking off rings from M-64s and uncrating fins. Loaded 14 trucks of salvage by 1830. Mission of M-64s pulled 2320. 25 ships."

The traffic problem at the Bomb Dump was somewhat alleviated by the improvements on the cement roads leading into it. Station Utilities in conjunction with local contractors completed a good part of this work during the month. Undoubtedly this will contribute to relieve any congestion of bomb service trucks and trailers during night operations and speed up traffic moving thru the area.

Special Automotive Section projects this month consisted of the construction of a portable hoist and a personnel carrier. The hoist was made from a hand winch and a set of wheels from a bomb-lift truck. This machine permits engines and other heavy assemblies to be lifted and moved with ease by one man. The carrier, used for transportation of personnel on the Station, was made from a salvaged bomb service trailer that was damaged at the Metfield Bomb Dump explosion. The major part of this work was done by the welding department.

In order to relieve shortages in critical materials and parts the Machine Shop completed 92 jobs. They consisted of modifying firing-pins for the Armament Section, making connecting-rod bushings, reaming valve guides, machining pulleys, and making nuts, shafts, shackle bolts, Cletrac steering brake pins, gas sediment bowls and wrenches. During this period, 116 repair jobs on vehicles cleared through the various departments of the Section. In addition, seven trucks and three chemical handling trailers were painted and stenciled.

The Armament Section during this month conducted tests on various types of muzzle boosters for caliber .50 aircraft machine guns to determine their effectiveness. These tests covered the use of boosters both in the air and on the ground, with the effects of altitude and climatic conditions carefully taken into consideration. The results of this experimentation proved quite satisfactory. All data assembled has been forwarded to higher headquarters.

One of the enlisted men of this unit, M/Sgt Howard F. Sinzinger, was the winner of first prize in the 8th Air Force Victory War Bond drawing. This included a five-minute telephone call to his parents in Westlake, Ohio, a three day trip to London, and dinner with several high-ranking officers of the 8th Air Force.

During the latter part of the month, several men were selected to participate in the 8th Air Force small arms marksmanship match. Practice firing of the carbine was held daily on the Station, and several times the men fired at a nearby range. A company 'touch' football team was formed to enter the Station League. Practice sessions were held nightly in the company area. Two men of this unit were selected to play for the Station team.

1 October to 1 November 1944

The introduction of MK-12, 500 # Navy bombs, during this period necessitated certain modifications on MK-12 fins, and MK-221 and MK-223 nose and tail fuses, respectively. These modifications, which were carried out by the Ammunition Section in cooperation with several men from the Armament Section, facilitated the placing of safety wires in both nose and tail fuses. This job necessarily had to be accomplished without delay because MK-12 bombs were being delivered to the squadrons for bombing operations.

A few excerpts from the Daily Activity Report of the Ammunition Section will illustrate how this project was integrated into the regular schedule of Bomb Dump activities:

"Monday: Three men in fuse shack. Four men stacking MK-12, 500# bombs. One man on detail filling in racks for parking trailers and trucks. One man unloading MK-12, 500# bombs. Two men moving ammunition to #11 shack from #5. Four hundred M-81 unloaded from convoy."

"Tuesday: Two ammo men and three armorers modifying MK-12 fuses. One man filling practice bombs. Other men stacking M-81 Frags. Convoy of M-64 unloaded by 1400 hours (100). Six men linking ammo. Mission of M-57 (27 ships) pulled."

"Wednesday: Two men in fuse shack. Two men filling practice bombs. Other men stacking M-81 Frags. One man helping armorers modify MK-12 fuses. Mission of M-57 (34 ships) pulled."

The Automotive Section during this period completed 121 third echelon jobs. The machine shop turned out 79 jobs, and the welders 150 jobs.

Apart from routine inspection and checking of aircraft machine guns, the Armament Section provided several men each day to the Bomb Dump. These men assisted in the modifications project discussed above and also carried out regularly assigned duties. In addition, the Armament Section handled all pre-elimination arrangements in the 8th Air Force Marksmanship Contest. Targets, carbines, ammunition, and cleaning materials were provided at the shop.

Two enlisted men of this unit attended school during this month. One man from the Automotive Section received a week's training in Cletrac maintenance, and the other from the Ammunition Section attended a two week's course in Ammunition.

On the night of 28 October this unit in conjunction with 1217th QM Co., Headquarters Squadron, and 867th Chemical Co., held a dance at the EM Club on this Station. As in the past this dance was very well attended and proved to be a very successful affair.

The Company Touch Football team played a number of games in the Station League during this month. Practice sessions were held several times a week in the Company area. Two enlisted men and one officer of this unit were selected to play on the Station Football Team, and two enlisted men were also selected for the Station Touch-Football Team.

In the 8th Air Force Marksmanship Contest the Company Team reached the semi-final round in the Station Tournament, being eliminated by the 578th Bomb Squadron. Two enlisted men of this unit were selected to fire for the Station Team which reached the final round in the 2nd Division elimination contest.

This unit takes pride in the fact that in the blood donor's campaign during this period, eighty per cent of all personnel with "O" type blood who were present for duty responded to the call. It was contributions of this kind that gave the Group its enviable record in this campaign.

1 November to 1 December 1944

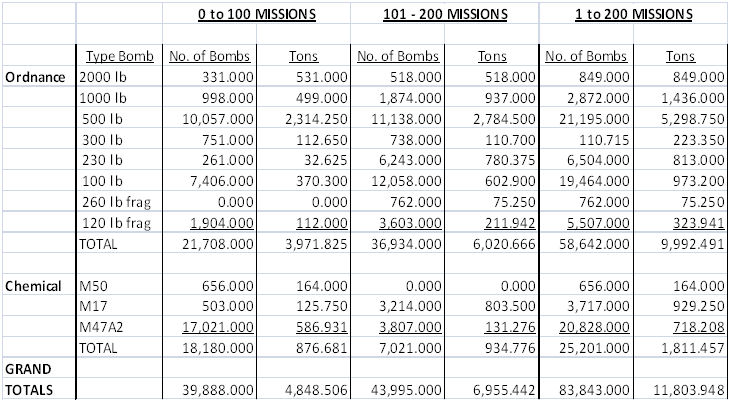

Inasmuch as 11 November 1944 marked the completion of the Group's 200th mission, a chart showing the number of bombs by tonnage and type, dropped "on target" from the 1st to the 100th mission, the 100th to the 200th, and the total, was prepared by the Supply Section of this unit. These figures were compiled from records and reports based upon intelligence interrogations after each mission. Totals for chemical bombs were included to make the picture complete.

The 100th mission is more than an arbitrary dividing line because this mission was completed on D-Day. Consequently, any comparisons between totals, tonnages, and types of bombs dropped in the two periods are pointed up by this fact. For instance, the increase of tactical bombing in support of ground operations, particularly during the early part of the invasion, is clearly in evidence from a comparison of the tonnages of 100 # demolition bombs, and 120# and 260# fragmentation bombs. Similar interesting and informative comparisons and analyses may be made on the basis of this chart. A representative of Station Ordnance was present at the interrogations to coordinate with S-2 the exact number of bombs loaded as per verbal reports received from the squadron Ordnance Sections prior to interrogations, also the exact disposition of all bombs used per verbal reports received from the bombardiers participating in the mission at the interrogations. The interrogations have also proved to be an excellent opportunity to gain first-hand and immediate information on any malfunctions of bombs or ammunition, and on bombs accidently dropped or jettisoned in England.

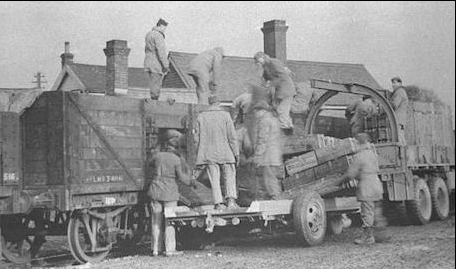

For some time one of the "bugs" in the Ammunition Area has been the need for additional equipment to facilitate and speed up the unloading of convoys coming in to the bomb dump. This problem was somewhat alleviated by the addition of an M 3 tractor to the organizational equipment of this unit. Plans were also completed for a trolley to be constructed by the Automotive Section, and to be used for the unloading of bombs more efficiently from convoy trucks to the stacks in the revetments.

During this period the 3rd Echelon Shop completed 103 jobs on vehicles. Among many of the interesting problems encountered was a DeSoto staff car equipped with a 1940 Plymouth engine. Inasmuch as no parts were available for the engine, a ¾ ton Dodge motor was installed in its place. This rather radical modification proved to be quite satisfactory. 138 jobs were turned out by the welding department. The biggest job tackled was a modification of fuel trailers which involved thirty 6 foot plates. A plate was bolted on each side of the frame above the rear tandem dual axle to prevent cracking of the frame. Each plate required twenty ½" holes which had to be drilled by hand. The machine shop truck was equipped during this period with a Sheldon lathe complete with all attachments. The machinists completed 78 jobs among which were the manufacture of miscellaneous items that are in short supply at the depots. Washers, king pins, center pins, bolts for shock absorbers, and brake pins for Cletracs were made for the Automotive Parts Shop; bolt studs and firing pins were made for the Armament Shop.

Since the supply depots require that small arms weapons be protected with a coat of cosmoline before shipment, the Armament Section constructed a tank equipped with a heating unit. As a result, weapons are now being returned to the depots packed and ready for shipment. The monthly inspection of all aircraft machine guns was carried out by the Armament Section along with an inspection of all small arms weapons on the Station. Arrangements were also made for all personnel of this section to go on TD with the Armament Sections of the squadrons for a period of two weeks. The men will thus have an opportunity to become familiarized with the proper procedure of loading bombs and ammunition on aeroplanes.

During this period several EM and one officer of this unit attended schools for the purpose of acquiring technical training in various branches of Ordnance. One EM from the Armament Section and one officer attended a three day course in Rocket Launchers and Grenades. In the Ammunition Section two EM attended a course on Mines and Booby Traps, and one EM a course on Ammunition. The Automotive Section sent two EM to school, one for a course on Cletrac Maintenance, and the other for a course on 3rd Echelon Maintenance of fuel service and truck tractor equipment.

In the field of sports, two EM and one officer of this unit were members of the Station Football Team. The Company basketball team was entered in the Station League and to date has played two games.

1 December 1944 to 1 January 1945

In an effort to speed up the unloading of convoys at the Bomb Dump, an M-3 Diesel-powered tractor crane was added to the equipment of the Ammunition Section. In addition, a new crane manufactured by the Hyster Company was received for experimental purposes. This crane is powered by a four-cylinder Hercules engine. There are three wheels, two dual chaindriven in front, and one dual in the rear by which the steering is done. The principal disadvantage of this piece of equipment is the fact that the overhead boom, which extends beyond the front of the vehicle, is stationary thereby slowing down unloading procedures. A few excerpts from the Daily Activity Report of this Section will point up the effectiveness of this new equipment in unloading operations:

"Sunday 16 Dec 44: Three men inspecting fuzes. Four men uncrating fins. Other men laying new floor-type dunnage for fins. Convoy of 208 M-64s unloaded in 1 hour 45 minutes from time of arrival (1345 hours), two "cats" being used in unloading. Alert of 100# bombs pulled in late evening."

"Monday 17 Dec 44: Alert crew slept and all the other men uncrated 100# bombs to have ready in the event of another 100# mission. In the afternoon 84 500# M-64s came in. Both cranes were used for unloading and it was completed by 1500 hours while another convoy of a scheduled 397 M-57 bombs came in. Only 172 of the bombs came in and the men started unloading at 1500 hours completing unloading by 2000 hours. The rest of the convoy was cancelled until the following day. No alert."

"Tuesday 18 Dec 44: Men restacked a pile of bombs that fell during the night. Rest of 300# convoy came in at 1200 hours plus an additional 168 bombs unloaded by 1500 hours. Mission of 250# M-57s unloaded first thing in the morning. Both 'cats' and 'Doodlebug' (Hyster crane) were used to unload. Fifty .01 detonators test-fired for defective lots. Men worked till 1215 hours. After returning from lunch they immediately unloaded second convoy. Mission of 500# M-64s pulled in evening.

Apart from routine duties at the Bomb Dump such as unloading convoys, inspecting fuzes, linking ammunition, issuing bombs to the Squadrons, and stacking bombs, the Ammunition Section completed several other projects. In compliance with instructions received from Eighth Air Force, MK-I and MK-II two-star red distress signals were modified with a new type sealing tape supplied by 3rd SAD. Orders were received from the Ordnance Officer at 2nd Air Division to test a number of each different lot number of .1 and .01 M-14 primers for detonators on hand. A total of 550 detonators were tested and three malfunctions were noted. These three were forwarded to higher headquarters for thorough inspection. During this period further emphasis was placed on the greasing of nose and tail plugs on bombs and efforts are being made to set up a procedure whereby these bombs will be more easily identified by the squadrons at night. This will be accomplished by placing a smear of yellow paint near the nose of each bomb after the plugs have been greased. This operation facilitates the fuzing of bombs by the Squadron Ordnance Sections.

The Automotive Section completed 76 3rd Echelon jobs at the shop. Among the most interesting was the installation of a Diamond "T" engine in an Auto Car tractor. This involved many modifications to insure a satisfactory result. The fuel system had to be changed from a down-draft to an up-draft type. Manifolds, carguretor, air compressor, oil filters, wiring and distributor were altered to give adequate clearance for the controls. The cab over engine type tractor hold all clearances to a minimum.

In the machine shop 101 jobs were completed, among which were the turning out of crankshaft bearings for a 3 K.V.A. generator, parts of a universal joint, and bolt studs and firing pins for the Station Ordnance Parts Section. The welders turned out 126 odd jobs varying from bomb cradles to the parts for a trolley device to be used in unloading convoys at the Dump. To date this device is still being layed out prior to assembly.

The policy of sending men to school to qualify them further for specialized work was continued during this period. The following courses were attended by enlisted men of the Automotive Section:

a. One week course on the assembly and dis-assembly of Cletracs.

b. Two week course on Air Corps special purpose vehicles and tractors.

c. Two day course on the weather-proofing of vehicles. This course covered the operations involved in cleaning and covering all parts of vehicles with rust-proofing and waterproofing solution.

d. One week course in Bomb Reconnaissance.

Beginning the 4th of this month and lasting thru the 16th all men of the Armament Section worked in conjunction with the Armament alert crews of the Squadrons, loading aircraft with bombs. One of the main reasons for this training was in the event an emergency ever existed on the field where there was a shortage of bomb-loading personnel, this section could be called on to help fill the gap. This job necessitated the rotation of personnel so that one man was on day shop duty and the rest were subject to night alerts. The second half of the month was devoted almost entirely to the inspection of caliber .50 machine guns mounted in aircraft, section personnel making an individual inspection of each gun.

A normal amount of third echelon repairs were also made on both aircraft guns and hand and shoulder weapons. In addition several new tools, such as a buffer spring removing tool and trigger spring removing tool for the carbine M1, and a gauge to determine the proper measurements on extractor and ejector assembly used on the Browning machine guns were made.

As in the past a man from Station Ordnance has attended the interrogations after each of the missions performed by the Group to ascertain the disposition of all bombs. This information has proved to be invaluable for many Ordnance purposes.

The Station Ordnance Bicycle Shop operated by one of the men from the Automotive Section, has been largely responsible for most of the third echelon maintenance on bicycles on the Station. Because of the scarcity of many bicycle parts it has been necessary to improvise on a rather large scale. For instance, rear wheels which are in short supply have been made from old parts that were on hand.

On 2 December, the day of the 200th Mission Party, an event of particular significance to this unit took place. Tec. 5 Christino M. Marquez, Section Armorer, was married to Miss Barbara E. Wright of Wendling, Norfolk. The marriage was solemnized in the Church of England, Wendling. Most of the men and officers of this unit attended both the ceremony and the reception which followed at the home of Miss Wright.

1 January to 1 February 1945

Due to the addition of a Diesel tractor and a Hyster Crane to the equipment of the Ammunition Section, loading and unloading operations at the Bomb Dump were carried out more efficiently during this period. While maintenance of vehicles became a factor of increasing importance it was more than offset by the man hours saved by the use of this additional equipment.

In compliance with 2nd Air Division Instruction No. 75-5 dated 24 December 1944 a system was devised whereby all special purpose vehicles on the Station were to be given a spot-check inspection once every week by the Automotive Section. Completed inspection forms are submitted to the Station Ordnance Office where letters are compiled listing all discrepancies and irregularities noted and forwarded for necessary action to the Station Commander. Inasmuch as there are 108 Special Purpose vehicles to check weekly, two men are assigned to this job at all times. During this period third echelon repair jobs at the Automotive Shop numbered 105, the machinists turned out 83 jobs, and the welders completed 147 jobs. Working conditions in the shop were somewhat improved by the installation of several portable Stewart Warner hot air blowers obtained from one of the Squadrons. Three flexible outlets (tubes) from each unit provide maximum coverage of the shop and are usually placed so that hot air blows over the job being worked on. An electrical bench constructed in the carpentry shop was devised by mounting voltmeters, ammeters, test leads, et cetera. This test bench has already proven its worth inasmuch as almost every generator and starter formerly returned to the depots for replacement, have been repaired or rebuilt by the automotive electrician, thereby keeping vehicles off deadline for much shorter periods of time.

The wrecking crew removed a demolished Mobile Training Unit van from under a B-17 which crash-landed in the Station Headquarters area. The body and bed of this Ford truck are beyond repair; however, the cab and chassis will be repaired by the shop. As a result of careful inspection and analysis of Cletracs which are sent to the shop for repair, it was voted in several instances that 1st and 2nd gear shift forks were broken. A UR complete with photographs and recommendations was submitted to higher headquarters so as to eliminate this faulty construction.

In compliance with a directive from 3rd SAD the Station Ordnance Office delivered report forms to every unit on this Station listing all Ordnance equipment authorized by pertinent T/O & Es, and OELs. These forms are to be completed by itemizing all Ordnance equipment on hand in the unit, thus giving Station Ordnance and the depot a complete and up-to-date record of all Ordnance property. In addition, to comply with a request from 8th Air Force Headquarters, a survey has been initiated to determine the number of caliber .50 A/C machine-gun parts required to maintain 100 guns for a period of one year. This survey required a statistical analysis of Stock Record Cards for the period of 1 Jan 1944 to 1 Jan 1945. In order to carry out tests to determine the desirability of mounting 4.5 rocket launchers on B-24 aircraft, launchers were obtained from 3rd SAD and the rockets picked up at the Ammunition Depot serving this Station. Training rockets were not available so the actual "live round" rocket was supplied. It will be necessary to remove the explosive charge in carrying out these tests as an added safety factor. In accordance with Station directives the Armament Section made provisions for the storage of all small arms of this unit. A new type of rust preventative was used in preparing these weapons for storage. This consisted in using ordinary Grade SAE 50 motor oil. It is expected that this oil in combination with waterproof crates and a dry storage building will preserve the guns for a period of 90 to 120 days. In addition to the normal amount of third echelon maintenance on A/C machine guns, personnel of the Armament Section carried out necessary modifications of the Navy MK13 1000# bombs, fuzes, and fins. These bombs were supplied to this Station to relieve the shortage of regular 1000# bombs. On several occasions, also, personnel of this Section demonstrated the proper procedure in manning and firing Station defense anti-aircraft machine-guns. This project was carried out for the benefit of men designated by the Squadrons as ground defense gunners.

During this period the practice of sending men to school for specialized training was continued. One EM from the Armament Section and one from the Automotive Section attended a week's course in Bomb Reconnaissance. The Ammunition Section sent three men to school: two to a Rocket and Grenade Launcher course of two days duration, and one to a British Bomb Disposal course of a month's duration.

Under the provision of General Order No. 8, HQ, 8th Air Force, dated 8 Jan 1945, this Company was reorganized under a new T/O & E. This latter authorized additional equipment for the unit, and additional ratings for both Officers and EM. The total strength of the unit remains the same.

On the night of 13 Jan 1945 this unit held a dance and party at the NCO Club, this Station, in conjunction with HQ Squadron, Medical Detachment, and 806th Chemical Company. As in the past this affair was well attended by all personnel.

Five EM of this unit were transferred to the 12th RD during this period in line with the recent allocation of Air Force personnel to the Army Ground Forces as Infantry replacements.

1 February to 1 March 1945

In order to accommodate all bombs stacked on roads both outside and within the revetments, the construction of a fifth revetment was begun. The addition of a bay on one end of two revetments and both ends of a third was also begun during this period. This latter project necessitated the moving of fins and bombs to make room for the extension of the blast walls. Nine more bays will be added to the present sixteen thus increasing revetment space about sixty-five per cent. The work is being done by a detachment from Headquarters Company, 867th Engineers.

During the first half of the month, four convoys consisting of 1195 M-64, 140 M-65, 30 MK-13, 1205 M-57, and 58 M-44 bombs were unloaded. Approximately 1900 of these bombs were stacked in two days, personnel of the Section working until 2130 hours each day. During the second half of the month, a total of 1783 500# bombs were unloaded. All convoys were cleared in record time, not exceeding three hours for any one convoy. Both the Diesel and Hyster Cranes were used in these operations. Excluding the 28th day of the month, a total of 1077 tons of bombs were dropped during the month of February.

During this period the usual daily inspection of fuses was made. In addition, an SOP was set up for daily inspection and check up on all vehicles assigned to the Ammunition Section. When the weather permitted a crew of men was put to work greasing nose and tail plugs on bombs. Several hundred 500# bombs arming wires were made due to the fact that arming wires returned after scrubbed missions are usually too short for reissue. Some of the wires, however, are salvaged. A general police-up of the Dump including restacking of scattered bombs was made whenever necessary.

The 3rd Echelon Automotive Shop completed 108 repair jobs during this period. Since rebuilt motors are not readily available at the present time, a considerable amount of 4th echelon work was included in this total. Spot checks on Air Corps special purpose vehicles resulted in additional work in the Shop.

The machinists had 79 jobs to their credit. Among the more interesting were the making of speed wrenches from old cranks to be used for removing and replacing nose plugs on bombs, and two large brass gears for the salt spreader used on the Station. In addition, several generator and starter armatures were turned on the lathe, and clutch shaft for a Cletrac was made. This Cletrac had been deadlined for some time.

The welders completed 117 jobs, and the bicycle shop turned out 30 3rd echelon repair jobs on bicycles.

All caliber .50 aircraft machine guns in excess of normal requirements were turned in to the Armament Shop by the Squadrons. The guns were thoroughly cleaned and coated with grade 30 motor oil, crated in specially prepared wooden crates, and shipped to the depot. It was also found necessary to rebuild and repair salvaged caliber .50 machine guns, test fire them, and return them to useable stock.

A caliber .22 rifle range was set up by personnel of the Armament Section in the Group Gunnery Building. This 1000 inch range, constructed of logs and sand bags with protecting walls of brick, is to be used by aircraft gunners in perfecting their sighting, aiming, and firing.

Personnel of this Section continued to modify the fins and fuses of MK-13 1000 lb Navy bombs which were unloaded at the Bomb Dump. Considerable time was also spent at the Chemical Dump drilling fins to accommodate smoke grenades, and converting the fuses for the special powder used.

A Report on suggested changes in Ordnance equipment authorized by T/E's of units on the Station was compiled by the Supply Section of this unit. Under present operating conditions it was suggested that a number of items be deleted from authorizations, and a few additions be made.

Tests were conducted by the Station Ordnance Officer and the Flying Control Officer to determine the feasibility of using parachute signal grenades in connection with landing aircraft.

Two enlisted Men of this unit attended school during the month of February. One from the Ammunition Section took a week's course in General Ammunition; the other from the Armament Section a week's course in Bomb Reconnaissance.

Four Enlisted Men of this unit were selected for Infantry Reinforcement Training and were transferred on 23rd February 1945.

The Company basketball team completed a very successful season and reached the semi-final round in the Station Tournament.

1 March to 1 April 1945

During this period a general police-up of the Bomb Dump was carried out by the Ammunition Section. Defective bombs were moved to a specified area and a further inspection of these bombs was made to determine which ones were repairable. All 500# T.N.T. bombs were moved to one stall thus facilitating loading operations for the squadrons. 36 bombs were set aside also for the purpose of long delay fusing only. A large percentage of 3rd grade ammunition was recovered for combat purposes as a result of a procedure set up during this month. After this grade of ammunition was delinked, it was divided equally among the four squadrons, then turned after thorough cleaning, for relinking, and is now ready to be issued for combat use. It is interesting to note that as a result of this, it was not necessary to link any 1st grade ammunition during the last half of the month.

At one period of the month it was necessary for the entire company to assist the Ammunition Section. Two missions of M-30 (100# bombs) and one mission of M1A1 frags (120# bombs) were called successively. The uncrating operation is time-consuming and therefore additional personnel were needed to have the required number of M-30s and M-1A1s ready. Six men of the Section assisted the squadrons in loading the mission of M-1A1 fragmentation bombs.

During the last half of this month, bombs were supplied on several occasions to other stations. 720 100# bombs were loaded between 0300 hours and 0600 hours one morning and shipped to Shipdham. 192 500# RDX, 38 M-57, and 10 300# bombs were loaded and shipped to various stations including Stations 104 and 114. An additional 72 M-57s were loaded for Station 125. The reason for this shifting of bombs between stations is to bring stocks of bombs up to complete mission levels. All odd amounts of bombs will be used thereby reducing inventories and easing transportation and convoy requirements.

A total of 1132 tons of bombs was unloaded during March. In this same period 1252 tons of bombs were dropped by the group. 57 trucks were loaded with salvage and sent to the depot.

The 3rd Echelon Repair Shop turned out 102 jobs during March. Several motors were completely overhauled, one requiring oversize pistons to be installed. The machinists handled 84 jobs, among which were the trueing-up of four GMC brake drums for the 3rd Echelon Shop at North Pickenham, and the re-cutting of a Dodge crankshaft journal which was damaged when a bearing burned out. 134 welding jobs were completed by the welding department.

The Armament Section spent the first half of the month primarily in repairing excess machine guns for shipment to the Base Depot, repairing, test firing, and in general reconditioning caliber .50 machine guns for Station Ordnance stock, and in inspecting the armament of operational aircraft. The Automotive Machine Shop cooperated in manufacturing various spare armament parts which are in critically short supply.

In accordance with existing practice, a monthly inspection was made of all caliber .50 AC machine guns and reports were submitted to the Group Armament Officer.

To further the safety program on the Station, a flag staff was raised at the firing-in butt so that a red danger flag can be flown whenever there is firing. A yellow flag indicates All Clear. Safety rules were defined and posted on large signs visible to all firing personnel.

Instructions were given the Armament Sections of all the Station units in connection with the modification of the hammer and hammer spring of the carbine M-1 and M-1A1. Hammers and hammer springs were supplied to each unit by the Station Ordnance Supply Section. Acting on orders of a higher command, a test was conducted under the supervision of the Station Ordnance Officer to determine the reaction of a partially filled B-24 AC bomb-bay gas tank when struck by a caliber .50 API projectile. The results of this experiment were forwarded to the requesting agency.

The Supply Section initiated Unsatisfactory Reports on the Savage 12 Gauge shotgun because of an excessive number of firing pins breaking; and also on the clutch housing on the F-1A fuel servicing trailer. These URs were forwarded to higher headquarters through channels.

Following enemy air activity over this Station on the night of 20 March 1945, a thorough reconnaissance of the perimeter, runways, and their environs was made the next morning. All personnel of the unit participated under the direction of the Station Ordnance Officer. Particular emphasis was laid on searching for anti-personnel bombs as there was an apprehension that the enemy raider might have dropped this category during his strafing. The reconnaissance lasted from 0730 to 1100 hours. Two unexploded 20# anti-personnel bombs of a new type were found near one of the hardstands. An RAF bomb disposal unit was notified and the necessary action was taken.

Two enlisted men, one from the Ammunition Section and one from the Supply Section, attended Ammunition School. This course is of two weeks duration.

On 26 Mach 1945 five enlisted men of this organization were transferred for Infantry Reinforcement Training. During the course of the month nine enlisted men were assigned to this unit, six combat infantry men and three men who recently arrived from the States.

On the night of 31 March 1945 this unit held a party and dance at the NCO Club in conjunction with Headquarters Squadron and 806th Chemical Company. As in the past this affair was well attended and was very successful.

1 to 14 April 1945

Exceptionally fine weather has contributed a great deal to the rapid completion of the additional bomb storage area now completed in the bomb dump. The 867th Engineers have been able to build the additional blast walls, concrete roads and bomb storage bays almost totally unhampered by rain or mud. It appears at this time, though, that these additional storage areas will not be utilized as the war in Europe is rapidly drawing to a close, and consequently the stock levels of all types of bombs and ammunition have been decreased almost fifty per cent by higher headquarters. This drop in stock levels was brought about by fewer convoys of bombs being shipped to this station during this period than usual, plus the fact that six convoys of bombs were shipped off this station to other stations for the purpose of raising their stocks up to "mission levels." The allied air offensive has in the meantime continued and nine missions of bombs were loaded during this period, one of which was scrubbed making a total of 369 tons of bombs dropped.

A shortage of caliber .50 machine gun ammunition necessitated a survey to be made of all such ammunition in storage and loaded in aircraft. Estimated requirements for a forty-five (45) day period were made on the basis of recent expenditures and all ammunition in excess of this level was shipped back to the depot for redistribution. Approximately 40,000 rounds of the 165,000 rounds of ammunition returned to the depot was formerly grade 3 training ammunition which had been re-processed by the squadron Ordnance sections, regraded to grade 1 Aircraft, and assigned a station lot number by Station Ordnance.

A general policing-up of the dump was made and 29 truck-loads of salvage were returned to the depot. Salvageable containers such as fin crates, detonator cans, signal boxes, etc., were also accumulated and placed in storage to be used for the repacking and re-shipping of ammunition remaining after the cessation of hostilities in accordance with instructions from higher headquarters.

Activities of the Third Echelon Shop were normal during this period, 38 Third Echelon jobs being completed. Due to the non-availability of ½ ton Dodge motors, two ¾ ton Dodge motors were mounted in half-ton vehicles with necessary modifications being made to the allied assemblies and parts. The machine shop completed 59 jobs, including a high priority job consisting of two new type airport landing launcher for flares, made from the barrels of .03 rifles. The armament section chief and machinist spent many long hours carefully planning, designing and constructing the launchers which were finished in time for immediate shipment. The welding shop completed 75 jobs and also designed an easily manufactured jeep muffler out of steel pipes and metal salvaged from practice bombs. These mufflers have been short in supply for some time and this idea will solve the supply problem completely. Two mechanics were placed on detached service at another station for two weeks to assist in preparing its vehicles for reshipment. The bicycle shop mechanic completed 23 3rd echelon jobs on station bicycles.

The Armament Section, having just recently completed its inspections of all aircraft machine guns, turned its efforts to the Bomb Dump to assist that section in bringing their work up to date. A few days were also spent in cleaning and repacking caliber .50 machine guns and small arms to be returned to the depot as well as modifying about 100 carbines by interchanging new type hammers and springs. The Armament Section Chief, T/Sgt Dreher, designed a new type, bomb shipping block device.

Two of these devices will be used on the lugs of each bomb which are to be shipped after cessation of hostilities, to other theaters. He has also set up a production line in the armament shop which can turn out 400 of these blocks per day. It is anticipated about 6000 of these blocks may be eventually required.

Within only fifteen days of the second anniversary of the activation of this company a sudden and complete change of its status took place. Late in the evening of 15 April 1945 a meeting of the service unit commanders on the station was called by Lt Col Wall, formerly commanding officer of 465th Sub Depot. Lt Col Wall announced that in accordance with Secret VIIIth Air Force, GO #52, dated 12 April 1945, the 10th station Complement Squadron, 465th Sub Depot, 1825th Ord S&M Co (Avn), 264th Med Disp (Avn), 208th Finance Section, 1217th QM Co, 1287th M.P. Co (Avn) and 2101st Eng F.F. Platoon, were disbanded as of 2400 hours 14th April 1945. In accordance with the same General Orders a new organization, the 403rd Air Service Group was activated, consisting of three (3) squadrons: 403rd HQ & Base Services Sq, 829th Air Engineering Sq and the 653rd Air Materiel Sq.

The problem immediately at hand was to form the three new squadrons by placing all the personnel of the disbanded units into one of the three new squadrons. It was then the unpleasant duty of the commanding officer and the 1st Sgt to split the company up and at 0400 hours the following morning the task had been completed. Inasmuch as the company was principally a supply and maintenance company the enlisted personnel were divided about equally between the Engineering and Materiel Squadrons, thirty-seven to the former and thirty-six to the latter. Capt Jack A. Teufel, formerly Commanding Officer, was transferred to the 403rd HQ & Base Service Sq, Lt Walter P. Haar to the 829th Air Eng Sq and Lt Charles E. Dye to the Air Mtl Sq, all within the new Service Group.

Thus is brought to an ending the history of the 1825th Ordnance Supply & Maintenance Co (Avn) which has made for itself, through the untiring effort of all concerned a record its members were proud of. This company as a unit will no longer exist, but the personnel will always carry on its name by their exemplary conduct, efficiency and achievements. Beyond any doubt, this company can be credited as having well done its part in bringing this war to an inevitable victorious end.

For additional information read THE MILITARY EXPERIENCES OF CHARLES E. DYE

Other Photos of the 1825th Ordnance Supply and Maintenance Co.